Some plastics learn to repair themselves

A self-healing material might help paints and plastics repair minor damage as it develops

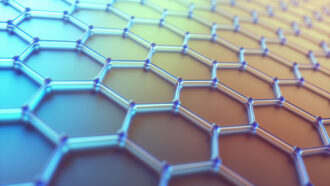

Polymers are an important ingredient in many materials, including the colorful plastics shown here. Scientists have developed a new polymer material to help repair small cracks that might develop in such polymer-based products.

XXLPhoto/iStockphoto

All the king’s horses and all the king’s men couldn’t help Humpy Dumpty. But maybe they’d have had better luck if H.D. had been made out of a material that can heal itself. Consider the type now being developed by scientists at Clemson University, in South Carolina.

When the new material becomes scratched or cracked, its separated molecules reconnect. This new self-healing material is made of polymers. Their building blocks are long chains of the same atoms or molecules. Such polymers are used in many paints, plastics and more. One day, these products may be able to repair any minor damage.

The self-healing property only works with small cracks. How tiny? In tests, cracks made with a razor blade that were about half the width of the thinnest human hairs healed themselves in about 14 hours. Cracks about twice as wide as the thickest human hairs took about three and a half days to self-repair.

A description of these new materials appears October 12 in Science.

Then again, it may be an exaggeration to say this damage truly self-repairs, argues Mostafa Yourdkhani. He’s a mechanical engineer at Colorado State University, in Fort Collins, who did not work on the project. The repair process for deeper cuts and cracks does require some outside help, he notes. Someone must put the pieces side-by-side so that they can re-bond. That’s one limit of the work. Ideally, he says, self-healing materials should fix themselves without a human hand.

The inspiration

Polymers can become damaged over time. If that causes people to throw damaged plastics and other polymer-based materials away, it will lead to a lot of trash. Scientists have sought self-healing plastics in hopes that products made from them would last longer. That should slow the rate at which things are discarded.

In one approach, researchers engineered materials to hold tiny capsules of some built-in liquid. When the material cracked, the capsules would break. As the liquid flowed out, it would fill the crack and then harden. In another approach, scientists chose polymers that, when heated, would melt back together.

Those are not what the Clemson group did. It took advantage of how polymers naturally arrange themselves.

Long polymer strands stick together because of what’s known as van der Waals forces. These forces arise from the interactions between atoms and molecules. They’re weaker than other forces, but over the entire length of chainlike polymer molecules, they can hold the material together.

Clemson materials scientist Marek Urban led the new project. He wondered if van der Waals forces could be used to create a self-healing material. This is a pretty new idea. Previous attempts at self-healing materials had focused on making new bonds between the molecules, such as by adding other materials (like the liquid in those microcapsules).

To test the van der Waals approach, Urban’s team started testing combinations of polymers. Once scratched, most of them would not heal. But after six or seven years, their investigation paid off. The researchers identified two simple polymers that, when mixed with water, naturally stuck together to form something new.

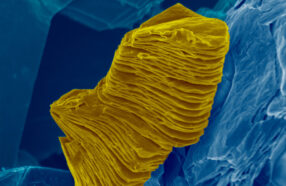

Even better, these polymers created structures that, under a powerful microscope, look like lots of little keys stuck in lots of little locks. Van der Waals forces hold the locks and keys together. Urban’s group discovered that when the material is damaged, the locks and keys separate. But when the two pieces get close enough, the van der Waals forces pull them back together into their original configuration.

Damaging this material is like peeling a clump off of a bunch of cooked spaghetti, Urban says. The polymer healing is like replacing the clump. The broken-off polymer strands now re-stick to the rest, he explains. The molecules reattach in the same way that they had initially connected, the new research shows.

That means the “healed” material ends up with the same structure as the original, says Yourdkhani. The new polymer also has a fairly simple chemical recipe, he adds.

“The material they used is based on an acrylate,” he notes. And acrylates (AK-rih-layts) are common, he adds. Plexiglass, he points out, is made from acrylate. As a result, he thinks it will be easy for companies that make paints, plastics and other polymer-based products to use it.

Urban agrees. “We don’t want to build a new factory to make new materials,” he says. “We want to tweak existing materials.”

This is one in a series presenting news on technology and innovation, made possible with generous support from the Lemelson Foundation.