Shape-shifting cuts give shoes a better grip

Inspired by animal claws and scales, the soles were crafted using a Japanese technique

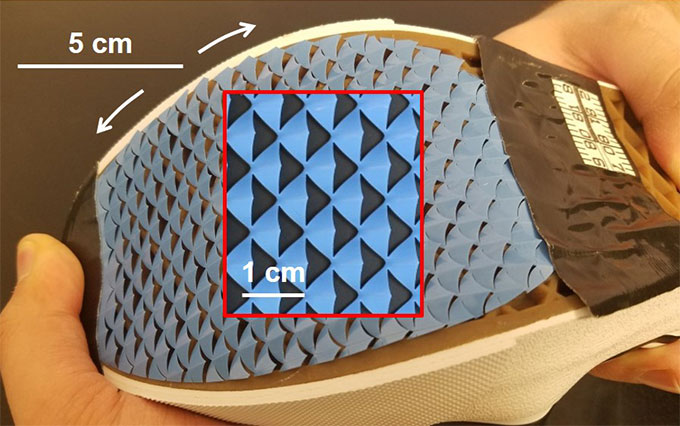

The Japanese style of cutting called kirigami transforms this shoe’s sole from flat to grippy as it flexes.

Diemut Strebe/Harvard SEAS

Cuts and folds can transform a flat piece of paper into a 3-D work of art. Such techniques can also create engineering solutions. Researchers have now used creative cuts to help shoes get a grip. With pop-out structures, the shoes’ soles go from flat to spiky as someone walks.

The new soles apply the Japanese art of kirigami. It’s like origami, but “instead of folding the flat sheet, you cut … along the specific pattern,” explains Sahab Babaee. A mechanical engineer, he uses physics and materials science to design devices. He works at the Massachusetts Institute of Technology in Cambridge. In addition to paper, kirigami can reshape sheets of wood, cloth or metal.

For their project, Babaee and his team carved a pattern of cuts into a thin, stainless steel sheet. Attached to the sole of a shoe, it stays flat as someone stands. But start to walk and the sole will bend and stretch to form structures that stick out.

Japanese artists have long used kirigami to craft decorations, notes Jie Yin. He’s a mechanical engineer at North Carolina State University in Raleigh who had no role in the new design. Kirigami is now coming to practical applications, he says. This new sole design is “a very cost-effective way,” he says, to “potentially prevent falls.”

It was also inspired partly by nature. “What are animals doing? They cannot go to the store and buy shoes,” says Katia Bertoldi. She’s a structural engineer at Harvard in Cambridge, Mass., who was part of this project. Cheetahs sink their claws into a tree trunk to climb, she notes. But the cats pull those claws back when they’re not needed. And snakes’ scales are arranged to create friction that helps them slither. Bertoldi and her colleagues took cues from these animals in looking for designs that would boost a sole’s grip.

Shape-shifting shoes

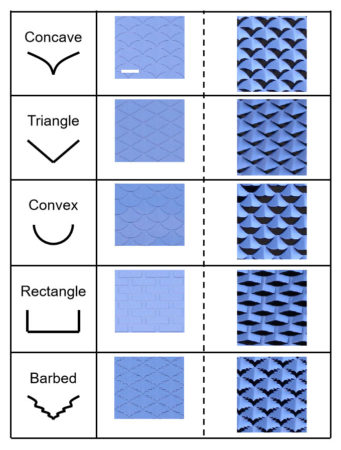

The researchers studied three types of structures. One was based on semicircles that folded out. Before bending, that pattern looks like fish scales. Another had rounded parts that folded in to produce very sharp spikes. The last used a triangle-based cut that looks more like snakeskin.

The team investigated how different arrangements of these designs affected friction.

Sometimes they put all the spikes in one direction. Other times, they arranged patches of spikes in different directions. Using a computer model, the team then calculated the friction each pattern would produce on ice, vinyl or hardwood floors. With a laser cutter, they cut some of the patterns into stainless steel and tested them. The sharp spikes seemed the most promising. They produced the highest increase in friction on ice. The team shared its findings June 1 in Nature Biomedical Engineering.

Volunteers helped test the prototypes in the lab. The recruits wore shoes with the sharp kirigami spikes attached and walked on ice. A device below the ice measured forces from the walking. This let the researchers calculate the friction due to the sole’s design. The grip boosted the shoes’ friction with ice by 20 to 35 percent compared to shoes such as winter boots that had a textured, but unchanging, sole, Babaee reports.

“This is a really creative design,” Yin says. But, he cautions, it may not work well on wet surfaces or ones made of sand or gravel. Water or those granules might get trapped in the shoe sole. Yin also wonders how long the grippers will last with all of that extra bending and rubbing.

Beyond soles

There’s a lot more to investigate with these grips, including other applications. “This is really just the tip of the iceberg,” notes structural engineer Evgueni Filipov. He works at the University of Michigan in Ann Arbor. In its current version, the new sole won’t protect the heel from slipping. A future shoe may be able to boost traction there. And beyond slips and falls, kirigami might someday help keep boxes from sliding in a truck. Or make handlebars on motorcycles that gain friction when they’re squeezed.

Kirigami doesn’t have to be just for scientists in a lab, though. The technique is so simple that students can experiment with it at home, Filipov says.

They may find interesting designs, as a student in Bertoldi’s lab did some time ago. That was what kicked off her passion for these structures. Almost by mistake, the student snipped a pattern and then observed how it popped. “It was just by chance,” Bertoldi recalls. But that curiosity led to the creative cuts their team is continuing to investigate.

Educators and Parents, Sign Up for The Cheat Sheet

Weekly updates to help you use Science News Explores in the learning environment

Thank you for signing up!

There was a problem signing you up.